Decomagna Ltd, the official distributor of Quick-Step flooring in Kenya. We specializing in laminate flooring, engineered wood, and click vinyl, made in Belgum. In addition, we proudly present Elora bespoke wood textile luxury cabinets, adding a touch of elegance to your space. With over 8 years of experience, we bring unrivaled expertise and class to every project. Trust Decomagna for exceptional flooring solutions and luxurious bespoke cabinets, all based in Kenya.

Discover Quick-Step: the renowned, durable flooring manufacturer made in Belgium, now exclusively available in Kenya.

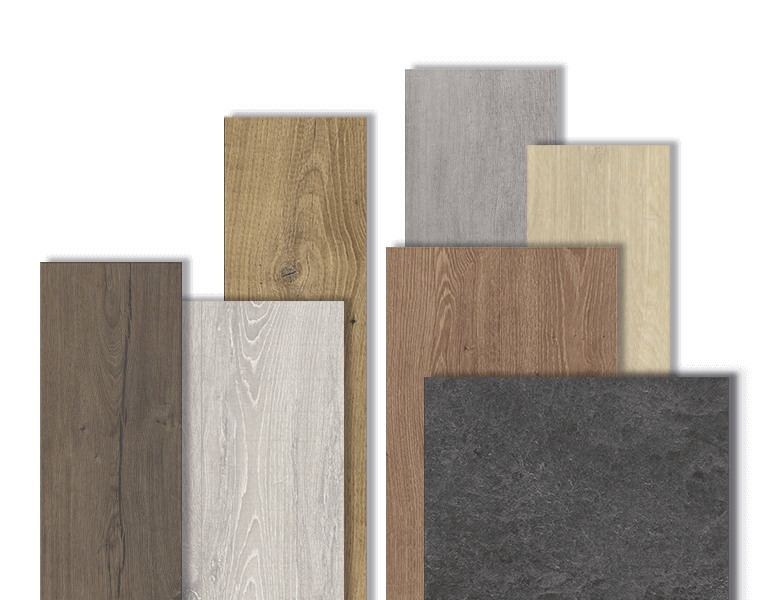

Our wide range of affordable flooring options comes with up to a lifetime warranty, ensuring long-lasting beauty and functionality.

With patented Uniclic technology, installation is seamless and hassle-free.

Quick-Step has received prestigious awards, including the Step-Forward Award and House Beautiful recognition, for its innovation and style.

Transform your space with Quick-Step laminate flooring and create an inviting environment with unmatched quality and durability.

Introducing ELORA, an exclusive line of bespoke custom joinery cabinets and doors made in Kenya by Decomagna. ELORA showcases exceptional craftsmanship and attention to detail, using high-quality textiles and wood joinery techniques.

Each ELORA piece is meticulously crafted to meet your specific requirements, allowing for a personalized touch that reflects your individual style. With a focus on quality and precision, ELORA joinery cabinets and doors elevate any space, creating a unique and sophisticated atmosphere.

Experience the artistry of ELORA, exclusively made in Kenya by Decomagna. From custom cabinets to exquisite doors, ELORA brings unparalleled craftsmanship and elegance to your home or space. Discover the beauty and quality of ELORA bespoke joinery that is tailored to perfection.

Buy Kenya Build Kenya